| KVA | Engine Model | Engine BHP | Controller | Specification Sheet |

|---|---|---|---|---|

| 7.5KVA (1Ph) CPCBIV+ | X2.5-G5 | 16.75 | PSO600 | Download |

| 7.5KVA (3Ph) CPCBIV+ | X2.5-G5 | 16.75 | PSO600 | Download |

| 10KVA (1Ph) CPCBIV+ | X2.5-G5 | 16.75 | PSO600 | Download |

| 10KVA (3Ph) CPCBIV+ | X2.5-G5 | 16.75 | PSO600 | Download |

| 15KVA (1Ph) CPCBIV+ | X2.5-G6 | 25.2 | PSO600 | Download |

| 15KVA (3Ph) CPCBIV+ | X2.5-G6 | 25.2 | PSO600 | Download |

| 18.5KVA (1Ph) CPCBIV+ | X2.5-G6 | 25.2 | PSO600 | Downlaod |

| 20KVA (3Ph) CPCBIV+ | X2.5-G6 | 25.2 | PSO600 | Download |

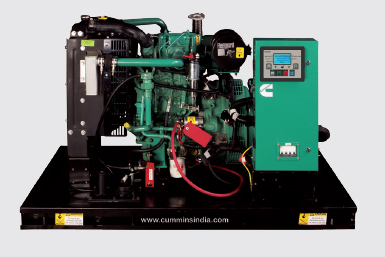

Engine

- Cummins® X2.5 series, 3 cylinder, In-line 4 stroke,

radiator cooled engine - Robust and efficient air handling system with

• Dry type, replaceable paper element air cleaner

with restriction indicator

• Optimized turbocharger for increased

altitude capabilities - Optimized fuel consumption with Inline fuel pump with A1

class mechanical governing - Spin on fuel filter

- Cooling system is designed and tested for 45°C ambient

conditions - Full flow spin on lube oil filter

- First fill of lube oil and coolant

- Electrical starter motor with soft start engagement feature

- Battery charging alternator

- 1 X 12 V DC battery

Alternator

- Stamford PI0,S0L1,S0L2 and PT0 alternator frames from

cummins Generator Technologies - Brushless type, Screen protected, Revolving field, Self

excited alternator conforming to IS/IEC 60034-1 - Better motor starting capability

- Best in class efficiency

- Compact design with sealed bearings for longer life and

lesser maintenance - Impregnation on all wound components for better

mechanical strength

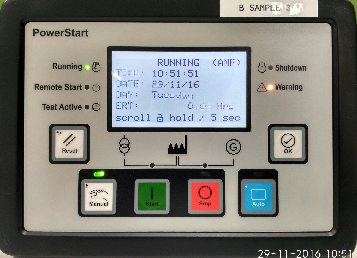

Genset Controller

- Cummins® PowerStart™ PS0600 control is a microprocessor based generator

set monitoring, metering and control system with LCD display designed to meet the demands of today’s engine driven generator set - AMF Functionality

- Intuitive operator interface which includes LED backlit 128X64 pixel graphic display with tactile feel soft-switches & generator set status LED lamps

- Remote start-stop

- Audible & Visual warning for Inducement

- Engine Metering: Oil pressure, Engine temperature, Starting battery voltage, Engine running hours

- AC Alternator Metering: L-L Voltage and L-N Voltage, Current (phase and total), kVA (phase and total) and Frequency. kwh, Total & per phase (kw & kVA), PF, Utility Voltage and Frequency

- Engine Protection: Low lube oil pressure, High/Low coolant temperature, Battery High/Low/Weak Volts, Fail to Crank/Start, Sensor failure, Cranking lockout, Low fuel level

- AC Alternator Protection: Over/Under Voltage, Over/Under Frequency, Loss of AC sensing. Overspeed, Over Current, kW Overload

- Data Logging: Engine hours, Control hours and upto 5 recent fault codes

- Configurable glow plug control

- 12 Volt DC operation

- Sleep mode

- Modbus interface (RS485 RTU)

- In Power compatible (PC based service tool) Certifications – meets the requirement of relevant ISO, EN, Mil Std. and CE standards

- Maintenance due alarm based on Engine Run Time and due date

- Exerciser scheduler

Control Panel

Control panel is powder coated for weather-proof and longlasting

finish. The control panel consists of the following parts:

- PS0600 Controller

- Bus bars with suitable capacity with incoming/

outgoing terminals - Indicating lamps for ‘Load ON’ and ‘Set Running’

Instrument fuses duly wired and ferruled - MCCB of suitable rating with short circuit protections

- AC/DC separation inside control panel for safety

Mounting Arrangement

- Engine and alternator are mounted on a common MS

fabricated base frame with AVM pads - Skid mounted radiator

- Base frame with integral fuel tank is provided with

drain plug, air vent, inlet and outlet connection and

provision for cleaning

Silencer

- Critical grade silencer suitably optimized to meet stringent emission standards laid down by MoEF / CPCB